Hydraulic Cylinder Repair Benches: Essential Tools for Efficient Repairs

In the world of hydraulic repair, precision and efficiency are crucial. Hydraulic cylinders are integral parts of various heavy machinery, from construction vehicles to factory equipment. With such a high reliance on hydraulic systems, hydraulic repair is a service that’s constantly in demand.

And when it comes to servicing these vital components, a hydraulic cylinder repair bench is an indispensable tool. At Cylinder Cyclone, we make servicing cylinders efficient with our cylinder repair benches.

But what is a hydraulic cylinder repair bench anyway, and how does it make cylinder repair and service easier?

Let’s dive into why this piece of equipment is so valuable in industrial settings and how it enhances repair operations.

Are you pumped to get started? Let’s go!

TL:DR - Hydraulic Cylinder Repair Benches

Hydraulic cylinder repair benches are an essential component in a cylinder repair business. The specialized bench allows technicians to perform teardowns, repairs, and rebuilds quickly, safely, and efficiently. This blog will discuss the features of a quality repair bench, how they improve workflow and reduce labor, applications of cylinder workbenches in various industries, and considerations when buying or upgrading a repair bench.

What is a Hydraulic Cylinder Repair Bench?

Hydraulic cylinder failures are no joke. These pressurized canisters require care, caution, and training to take apart and reassemble safely. That’s where hydraulic cylinder repair benches come in.

A hydraulic cylinder repair bench is a specialized work surface designed for the repair, rebuilding, and maintenance of hydraulic cylinders. Think of these benches as an extra set of powerful hands to assist the technician.

These repair benches are built to handle the heavy-duty nature of hydraulic cylinder components, which often include large pistons, rods, and seals. Regular workbenches simply can’t accommodate the weight and complexity of these parts, so a dedicated repair bench is a necessity for performing high-quality repairs.

In addition to providing a stable surface, many repair benches come equipped with features such as hydraulic presses, lifting arms, and adjustable workstations to facilitate the disassembly and reassembly of hydraulic cylinders. Without these specialized features, tasks like removing stuck seals or inserting large piston rods could be both dangerous and inefficient.

Hydraulic cylinder repair benches are designed to simplify these tasks, ensuring that repairs are completed quickly, safely, and correctly.

Key Features and Components of a High-Quality Repair Bench

When selecting a hydraulic cylinder repair bench, consider these features to ensure optimal performance and reliability. Here’s what you can expect from a high-quality repair bench:

- Adjustable Lifting Mechanisms: These mechanisms enable the lifting and positioning of large hydraulic cylinders, thereby minimizing manual lifting and reducing strain on technicians. Lifting arms or integrated hoists make it easier to handle heavy cylinders, preventing accidents and injuries that could occur from improper lifting.

- Hydraulic Press: A vital tool for disassembling hydraulic cylinders, the hydraulic press provides the force necessary to remove stubborn seals, pistons, and other parts. Whether you're extracting a broken part or pressing in a new one, a hydraulic press makes these tasks much more manageable.

- Rotating Tables: These allow the technicians to turn the cylinder without needing to move it, reducing the risk of injury. The ability to rotate the cylinder to the correct position helps in aligning components and makes the entire repair process more efficient.

- Heavy-Duty Frame: The repair bench's frame should be made from durable, high-strength materials, such as steel, to ensure it can withstand the weight of large hydraulic cylinders and the heavy-duty tools used in repairs. The frame must also be stable enough to prevent wobbling during use, as this could compromise the precision of the repair.

- Integrated Tool Holders: Organization is key in a repair shop. A well-designed hydraulic cylinder repair bench features storage options, such as tool racks or holders, making it easier for technicians to access the right tools quickly. These features help keep the workspace neat and efficient.

- Drainage and Cleanup Stations: During hydraulic repairs, fluid spillage is inevitable. A good repair bench will have integrated drainage or cleanup stations to handle hydraulic fluid leaks. This not only keeps the workspace clean but also ensures that technicians work in a safe, non-slip environment.

How Repair Benches Improve Workflow and Reduce Manual Labor

One of the most significant advantages of using a hydraulic cylinder repair bench is the improvement in workflow. Traditional methods of hydraulic cylinder repair often involve lifting heavy cylinders by hand, manually positioning parts, and using basic tools that may not be up to the task. This process is not only time-consuming but also dangerous. A repair bench with adjustable lifting features minimizes manual labor and reduces the likelihood of injury, particularly when handling large and cumbersome cylinders.

Additionally, the built-in hydraulic press and rotating features accelerate the disassembly process, enabling technicians to work on multiple parts of the cylinder simultaneously. This reduces downtime, which is crucial for businesses that need to get machinery back in operation quickly.

By having all the necessary tools and equipment in one location, repair technicians can work more efficiently. They don’t need to search for the right tool or waste time adjusting the cylinder position repeatedly. The integration of hydraulic presses, rotating tables, and specialized measuring instruments enables technicians to perform repairs more quickly, accurately, and with less effort.

Finally, hydraulic cylinder repair benches are often designed to streamline the entire repair process, allowing for easier disassembly, cleaning, inspection, and reassembly. The reduction of manual labor means that fewer technicians are required to handle each repair, resulting in higher productivity and cost savings in the long run.

Who Benefits Most from Using Cylinder Repair Benches?

Several industries that rely on hydraulic equipment can significantly benefit from using hydraulic cylinder repair benches. Here are some of the key sectors:

- Construction: Heavy machines, such as excavators, bulldozers, and cranes, rely on hydraulic cylinders for their operations. These machines experience constant wear and tear, making regular maintenance crucial. Hydraulic cylinder repair benches enable efficient repairs, minimizing downtime and ensuring construction projects stay on schedule.

- Agriculture: Tractors, combines, and other farming equipment use hydraulic systems that need regular maintenance. A repair bench can facilitate quick repairs, keeping machinery running smoothly throughout the planting and harvesting seasons. This is especially important during peak agricultural periods, when machinery downtime can result in significant losses.

- Manufacturing: Factories that use hydraulic presses or other heavy equipment can reduce downtime by having a dedicated repair bench for cylinder maintenance. Whether it's a large press used in metalworking or a lifting mechanism in a warehouse, having a reliable repair bench ensures that any issues get addressed quickly and without disrupting the workflow.

- Mining: The harsh conditions in mining operations put a strain on hydraulic machinery. Mining equipment, such as excavators, drills, and conveyor systems, often utilizes hydraulic cylinders. These components need regular repair and maintenance to ensure they function properly in challenging environments. A repair bench allows technicians to perform repairs on-site, minimizing equipment downtime.

- Aviation and Aerospace: Hydraulic systems in aircraft, landing gear, and other aviation technologies require high-precision repairs to prevent rapid unscheduled disassembly. The right repair bench can help technicians ensure that hydraulic components are serviced to the highest standards of accuracy and safety, which is crucial in the aerospace industry.

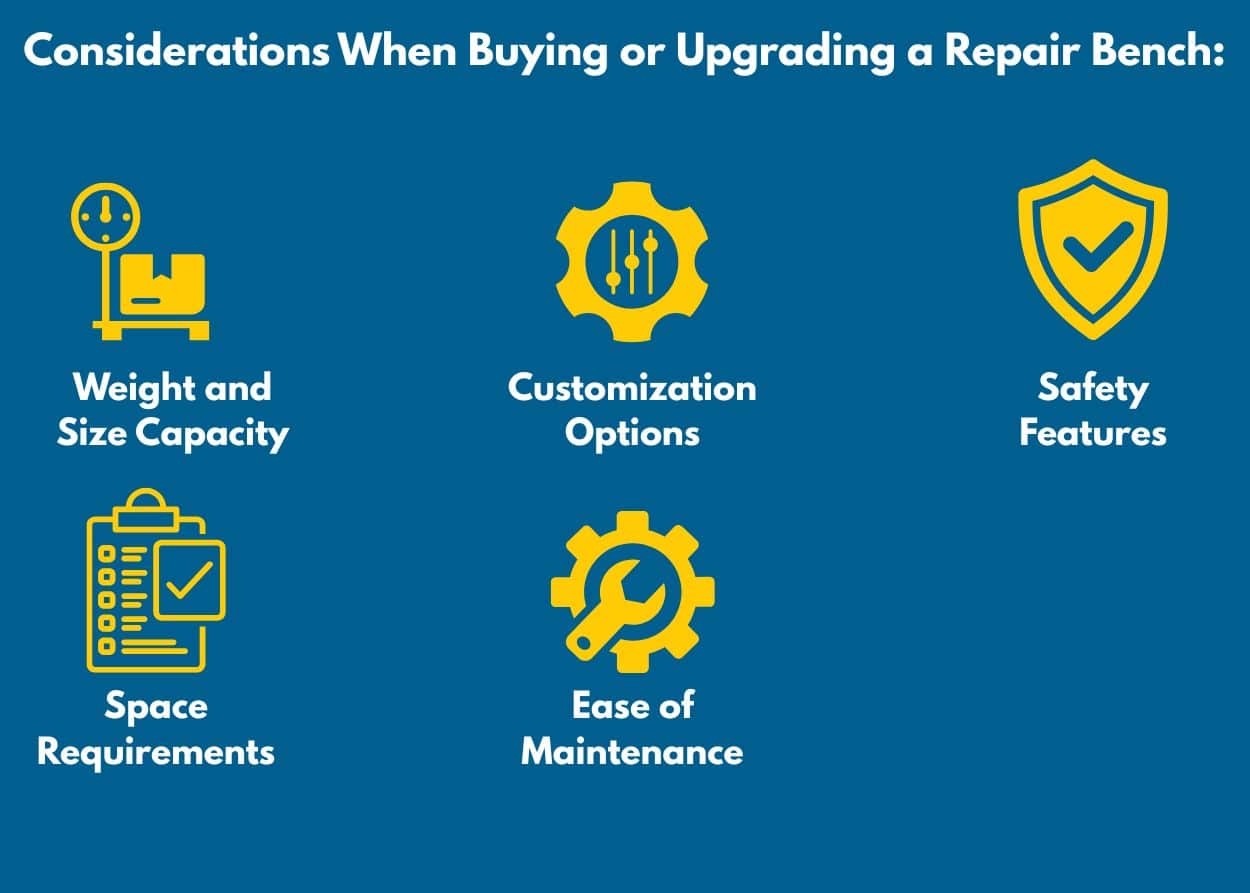

Considerations When Buying or Upgrading a Repair Bench

No matter where you purchase or upgrade your hydraulic cylinder repair bench, there are a few factors and features you should keep an eye out for:

- Weight and Size Capacity: Ensure that the bench is capable of handling the size and weight of the cylinders you typically work with. Some benches have weight limits, so choose one that can accommodate your heaviest repairs. A bench that can support a wide range of cylinder sizes is ideal if your shop handles multiple types of equipment.

- Space Requirements: Repair benches come in various sizes. If space is limited, a more compact design might be necessary. However, if you handle large cylinders regularly, a larger, more robust bench will be a better fit. You’ll also want to factor in additional space for tools, equipment, and movement around the bench.

- Customization Options: Look for a bench that can be customized to suit your needs. For example, adjustable features or additional tool storage might be beneficial depending on your specific repair needs. Customization can also include specific hydraulic features, such as presses with varying pressure capacities.

- Ease of Maintenance: Choose a repair bench that is easy to maintain and clean. Hydraulic fluid leaks or dirt buildup can interfere with the repair process, so ensure the bench has features that simplify maintenance. Look for benches with smooth surfaces that are easy to wipe down and maintain in a clean condition.

- Safety Features: Safety should be a top priority. Ensure the bench includes safety features such as secure locking mechanisms, non-slip surfaces, and guards to prevent accidents, as well as additional devices that enhance safety, like remote controls. Hydraulic repairs involve working with high-pressure systems, so it's crucial that technicians have a safe environment to perform their tasks.

Conclusion

Hydraulic cylinder repair benches are an essential tool for any hydraulic repair shop or maintenance department. They not only enhance the efficiency of repairs but also improve safety and reduce labor costs. By streamlining the entire repair process, these benches enable businesses to get machinery back in service faster, preventing costly downtime. Whether you’re in construction, agriculture, manufacturing, or any other industry that relies on hydraulic systems, investing in a high-quality repair bench is a decision that will pay off in the long run.

At Cylinder Cyclone, we offer innovation from the ground up, from the center pipe design that handles all pressure and torque forces, as well as the machine’s oil reserves, to the overhead Sky Hook system, which makes hoisting, alignment, assembly, and disassembly an easier and safer task. Every unit is offered with a complete set of custom-designed tooling, which will streamline every phase of cylinder repair and testing at your shop.

Why work with less efficiency? Contact us today for a no-pressure discussion on how we can match the right bench with your shop!