Efficient | Safe | Strong | Feature-Rich

As an equipment shop or service department in Tennessee, do you need a faster, safer, and more efficient way to tear down, rebuild, and pressure-test hydraulic cylinders?

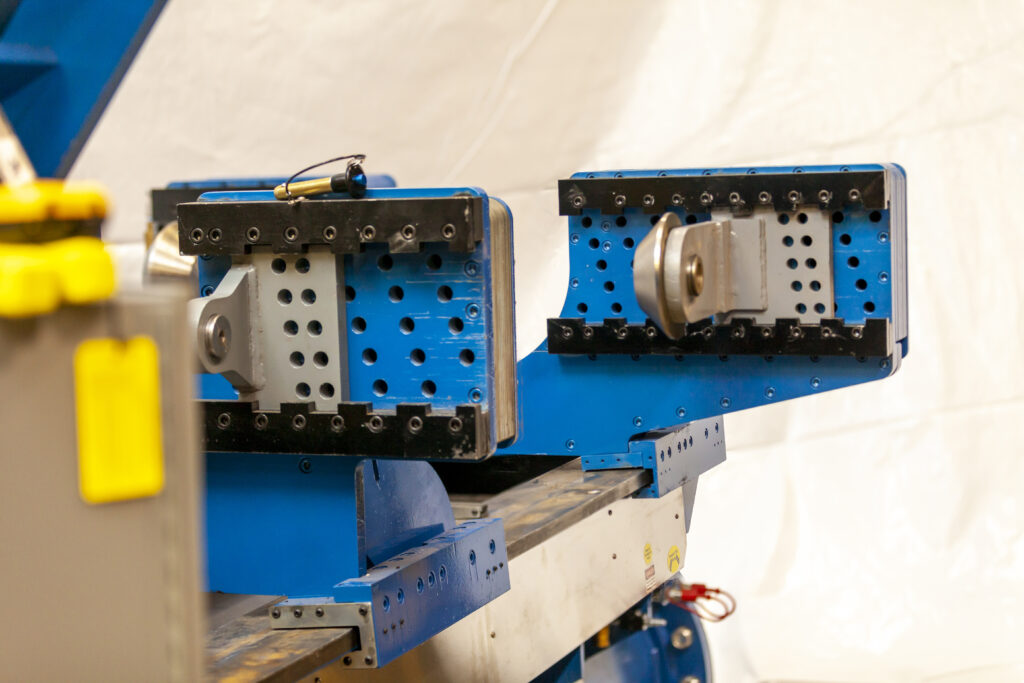

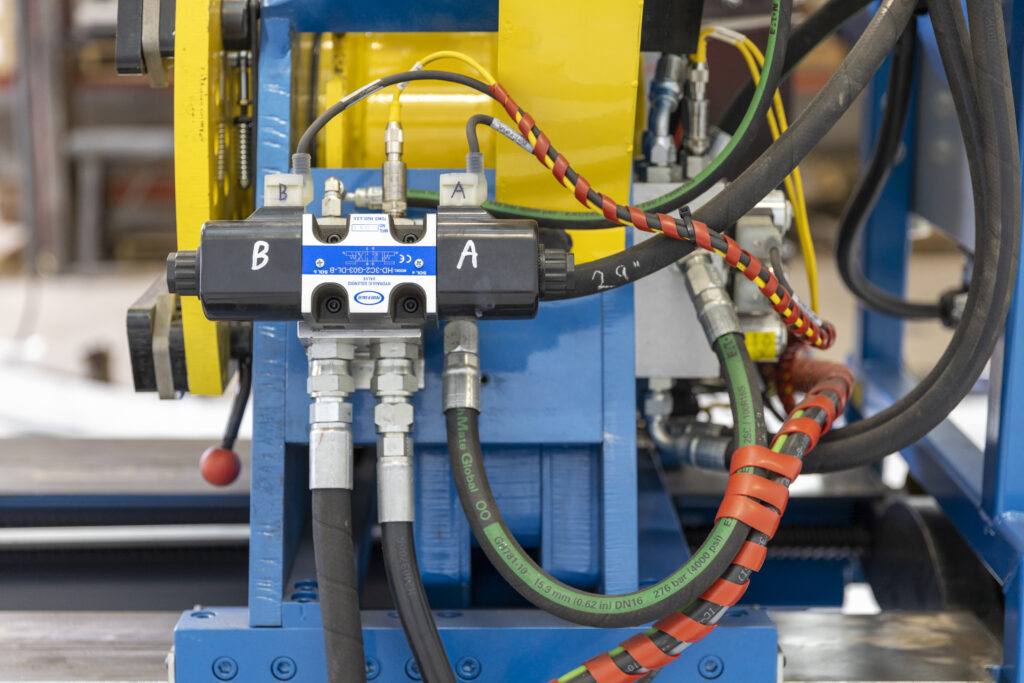

At Cylinder Cyclone, our premium cylinder-rebuilding machine includes bi-directional torque up to 60,000 foot-pounds, digitally controlled torque, and an integrated pressure-test system allowing you to rebuild cylinders faster and safer.

You can improve your hydraulic repair shop's ROI and efficiency!

What Makes Our Hydraulic Cylinder Repair Bench Unique in Tennessee?

We have experienced the frustrations and safety concerns of repairing hydraulic cylinders. That’s why we developed a premium cylinder-rebuilding machine that reduces average time by 50%-80%.

Enjoy a machine designed and built by cylinder shops for cylinder repair shops in Tennessee!

Download our catalog for our complete list of specs, tooling equipment, and more!

Here is why you should choose our hydraulic cylinder repair benches in Tennessee

-

Knowledgeable sales team that matches your shop or service department with the right tooling kits, pressure test fittings, etc.

-

Service department who answers questions quickly

-

Set up and on-site training is available

-

Financing available

You can transform your cylinder's shops ROI

On average, our customers pay off their machine in less than 2 years when using suggested bench charges for 2 average excavator cylinders or 1 hour of machine time per day!

How To Get A Hydraulic Cylinder Repair Bench in Tennessee

1.

Talk To Our Team

Let us know more about your shop and cylinder repair goals.

2.

Receive A Quote

We give you a quote with the configuration you need.

3.

Down Payment

Submit a purchase order and down payment.

4.

Enjoy Increased Efficiency!

Receive your machine and enjoy a faster and safer cylinder repair operation!

Enjoy The Ultimate Hydraulic Cylinder Repair Benches in Tennessee

Our Hydraulic Cylinder Repair Benches service brings on-site precision bench repairs and diagnostics to hydraulic cylinders of every size across Tennessee. From seal replacements and rod realignment to pressure testing and contamination remediation, our mobile technicians arrive equipped with calibrated load stands, genuine OEM seals, and high-tolerance alignment rigs. Whether you’re running a small press in Jackson or a heavy feeder in Memphis, we standardize repair protocols and stock a full range of components to minimize downtime. Rigorous pressure certification and detailed failure analysis extend cylinder life, keeping your operations—from Nashville’s manufacturing hubs to Knoxville’s industrial plants—running smoothly.